Description

- 1/2 HP commercial grade motor

- 1750 Pulses per minute (PPM) pulsating pump

- Requires a dedicated 20-amp or two separate 15-amp circuits

- 8’ x 5/8” ID service hoses

- 10 gallon powder coated tank

- 3.2 GPM flow rate

- 1500 Watt in-tank heater set at 140°F

- Temperature gauge

- Low fluid heater cutoff float switch

- Flush with or without heat

- Two non-bypass spin-on magnetic replaceable system filters (#40300272)

- 1” Drain plug allows for easy draining and cleaning of tank

- 10” semi-pneumatic rubber tires for easy mobility

- 5 GPM Flowmeter

- Initial system purge valve to prolong life of filters and fluid in tank

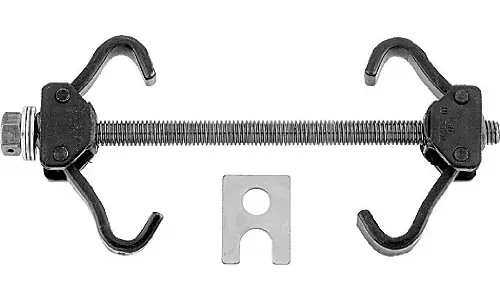

- Reverser valve allows easy flow reversal without removing service hoses

- Air purge allows for easy fluid removal from system and service hoses and air injection for added scrubbing

- Tool tray and bracket

- Domestic, Banjo and Honda adapter sets

- 1 Year Manufacturer Warranty

G-TEC heated flushers eliminate comebacks and mechanical failure!

Why use a Heated Flusher?

Transmissions usually fail at high temperatures. Automatic transmission fluid (ATF) gets filled with debris and contaminants. As the heat exchanger cools, the debris is trapped in the exchanger.

In cooling, the trapped debris and waxy varnish solidify. Cold solvents and aerosol cans cannot expand the exchanger or re-liquefy the contaminants. Only heating the ATF in the cooling system back to high temperatures will melt and flush out the cooler system thoroughly.

G-TEC heated flushers quickly and easily remove this contamination by safely heating and melting the waxy varnish and purging the particles and contaminants from the cooling system, a process proven to minimize the likelihood of comebacks and repeat repairs.