Description

- Very Accurate Ion Balance (± 10V)

- LED Light for Dust Detection

- Powerful Airflow (up to 87psi)

- Silent Nozzle (only 77.3 dBA)

- Ultra Lightweight (only 0.44 lbs)

- No External Transformer

- Long Power Cable (16.4 feet)

- Designed for Industrial Use

When plastic injection molded parts are pulled off the mold, the surface of the product is charged with static electricity. This static electricity from the part draws dust particles from the air to stick onto the surface of the product.

During a painting process, such dust may cause painting defects. The dust may show up on the finished coat and the surface may not be evenly painted (or coated).

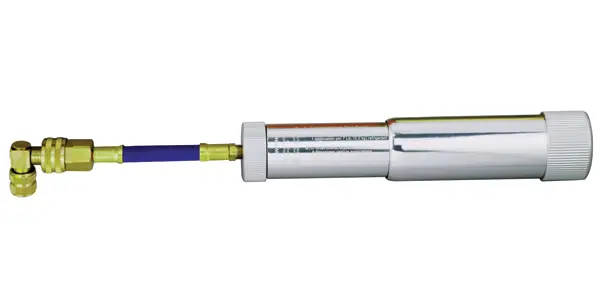

To avoid such defects, Vessel’s BBZ-E nozzle-type ion gun can be used to neutralize and eliminate static electricity, and to effectively clean the surface of the part before the general painting or coating process.

Unlike the Vessel BBZ-E ion gun, the traditional static eliminating system would consist of an air gun to discharge ionized air for neutralization, a large transformer to generate high voltage, and a high-voltage cable to connect these components. However, there are some issues with this type of setup. For instance, a large bulky external transformer takes up valuable space and cannot be installed at various work sites. Also, since the cable is constantly bending, it’s prone to break or disconnect which may cause an electric shock.

Other Surface Cleaning Examples

- Optical Parts / Lenses – before clear coat or protective coating

- Injection Molded Parts – before painting or chroming process

- Large Trays, Bins, Bottle – before labeling, filling with liquids, etc.

- Silk-Screening Process – remove dust before applying ink

ATD Tools 5612 - 11 pc. Noid Light Set

ATD Tools 5612 - 11 pc. Noid Light Set  Replacement Inner Screw and Nut Kit Bulldog 12,000 Lbs Trailer Jack

Replacement Inner Screw and Nut Kit Bulldog 12,000 Lbs Trailer Jack  Red Led Marker Light, 1" X 4", Optronics Brand

Red Led Marker Light, 1" X 4", Optronics Brand  Genius Tools 282262S - 1/4" Dr 72-Teeth Flex Head Ratchet with Rubber Handle

Genius Tools 282262S - 1/4" Dr 72-Teeth Flex Head Ratchet with Rubber Handle  Koken 3300MZ-10 - 3/8" Sq. Dr. 6 Point Deep Socket

Koken 3300MZ-10 - 3/8" Sq. Dr. 6 Point Deep Socket  Mastercool 53825-4 - Four Universal Dye Cartridges

Mastercool 53825-4 - Four Universal Dye Cartridges  Trailer Hitch 7 Way RV Wiring Kit For 17-25 Honda CRV Plug Prong Pin Brake Control Ready

Trailer Hitch 7 Way RV Wiring Kit For 17-25 Honda CRV Plug Prong Pin Brake Control Ready  Trailer Tow Hitch For 96-24 Chevy Express GMC Savana Van Class 3 5K 2" Receiver

Trailer Tow Hitch For 96-24 Chevy Express GMC Savana Van Class 3 5K 2" Receiver  Gooseneck to Fifth Wheel Trailer Hitch Conversion Adapter 18K for Draw-Tite Bulldog B&W 9480

Gooseneck to Fifth Wheel Trailer Hitch Conversion Adapter 18K for Draw-Tite Bulldog B&W 9480  445 Fence Stretcher-Splicer Wire Guides

445 Fence Stretcher-Splicer Wire Guides  ATD Tools 80075 - Heavy Duty Incandescent Utility Light With 25 Cord

ATD Tools 80075 - Heavy Duty Incandescent Utility Light With 25 Cord  OTC Tools 6667 - Harmonic Balancer Puller for GM/Chrysler/Mitsubishi

OTC Tools 6667 - Harmonic Balancer Puller for GM/Chrysler/Mitsubishi